Porter Precision offer a wide range of coatings to enhance the wear resistance and reduce galling. From basic chrome plating to today’s multiple layer coatings Porter has worked to give the end user the best possible surface for his need. While every application is different, Porter can assist you in determining the best coating for your application. Through the years Porter has furnished customers with various coatings and treatments to increase wear ability. From basic chrome plating to today’s multiple layer coatings Porter has worked to give the end user the best possible surface for his need.

>> Get A Quote

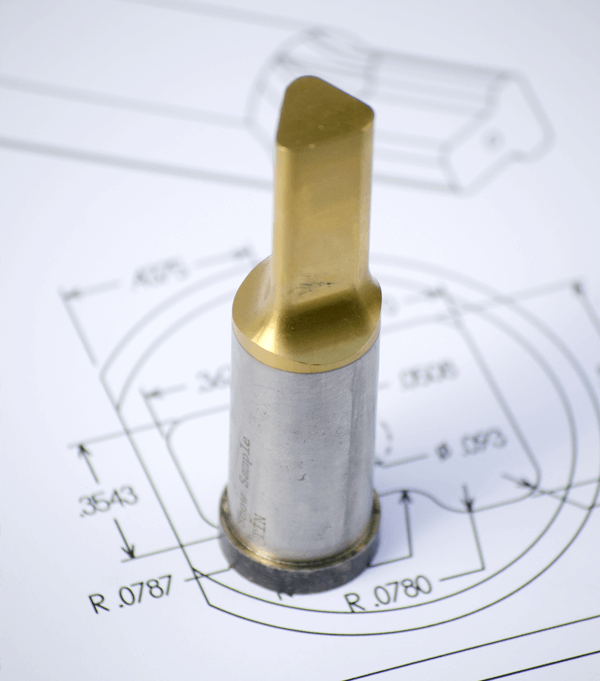

TiN (TITANIUM NITRIDE)

TiN (Titanium Nitride)

A (PVD) process of placing a thin coating of Titanium Nitride 1-5 microns thick over the working area of the punch.

Benefits:

- Surface hardness of 2300 Vickers

- Dry coefficent of friction versus steel .4

- Thermal stability up to 1100 F

Appears gold in color

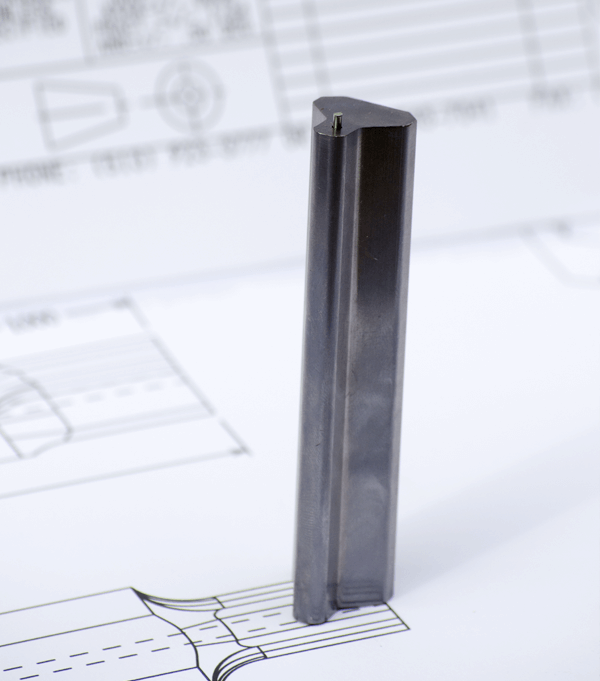

TiALN (TITANIUM ALUMINUM NITRIDE)

TiALN (Titanium Aluminum Nitride)

A (PVD) process of placing a thin coating of Titanium Aluminum Nitride 2-5 microns thick over the working area of the punch.

Benefits

- Surface hardness of 3000 Vickers

- Dry coefficent of friction versus steel .6

- Thermal stability up to 1292 F

- Appears grey

TiCN (TITANIUM CARBONITRIDE)

TiCN (Titanium Carbonitride)

A (PVD) process of placing a thin coating of Titanium Nitride 1-5 microns thick over the working area of the punch.

Benefits

- Surface hardness of 3000 Vickers harder than Carbide

- Dry coefficient of friction versus steel .3

- Thermal stability up to 750 F

- More wear resistance than TIN

Appears brown or light blue.

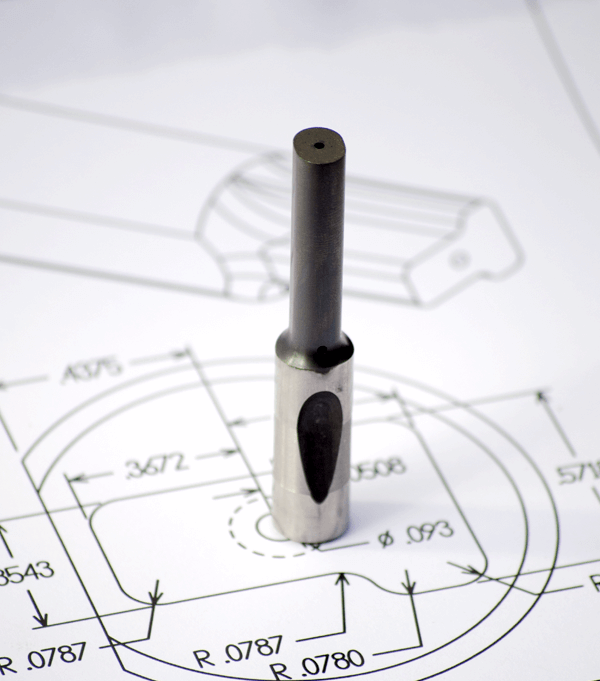

P-41

P-41

A (PVD) process of placing a thin coating 1-8 microns thick over the working area of the punch.

Benefits

- Surface hardness of 2000-2800 Vickers

- Dry coefficient of friction versus steel .1

- Thermal stability up to 550 F

- More wear resistant than TICN

- Specially for non ferrous materials

Appears grey or black in color.

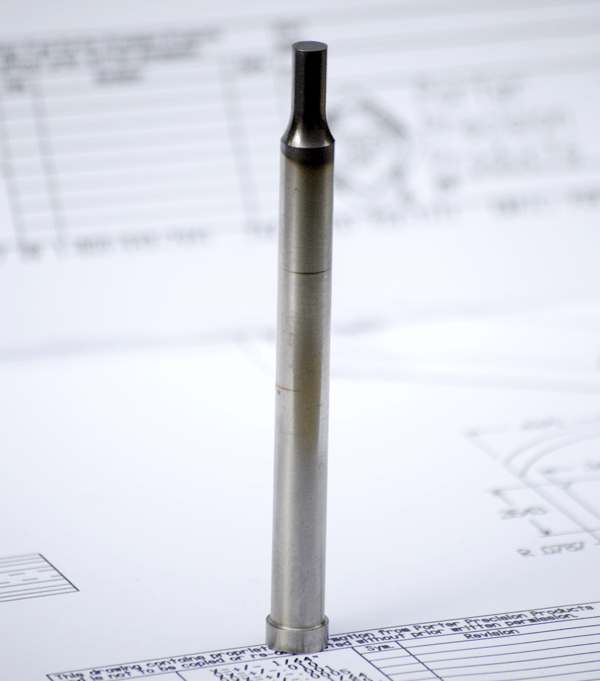

P-90

P-90

A (PVD) process of placing a thin coating 6-8 microns thick over the working area of the punch.

Benefits

- Surface hardness of 3800 Vickers

- Dry coefficient of friction versus steel .12

- Thermal stability up to 750 F

- More wear resistant coating

Appears silver-grey

PPC (PORTER PLUS)

PPC (Porter Plus)

A (PVD) process of placing a thin layer of this special coating (2-5 microns thick) over the working area of the punch.

Benefits

- Surface hardness of 3200 Vickers

- Dry coefficient of friction versus steel .35

- Thermal stability up to 2000 F

- More wear resistant than TICN

Appears blue-grey